Foamed polystyrene is one of most important insulating material, however, the problem installed on the wall of buildings are flammability.

Recently, many fire accidents have been reported all over the world.

Our “polymer degradation” group is interested in the relationship between the flow speed and flammability of melted insulating material. Therefore, we are now investigating in-situ visocity, tangent delta, and volume change of XPS during approaching to the melting point using DMA and rotary viscometer in controlling temperature.

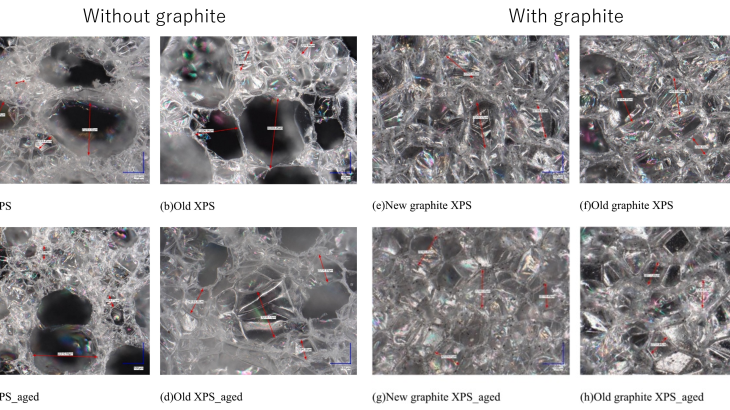

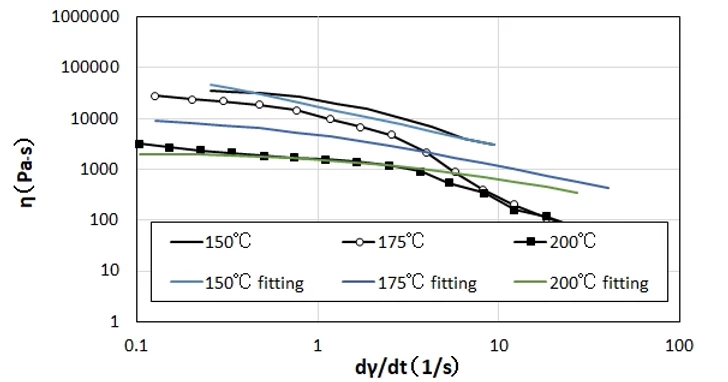

Viscoelasticity of XPS(extruded polystyrene foam) was often investigated during foaming process because it was a production process. However, vicoelasticity of melted foamed XPS is naturally different from foaming XPS. Porosity is continually changing as well as capillary number. As a result, the relationship between visocity and shear rate does not ride on Cross WLF function, which could explain the temperature dependency of most polymer viscosity.

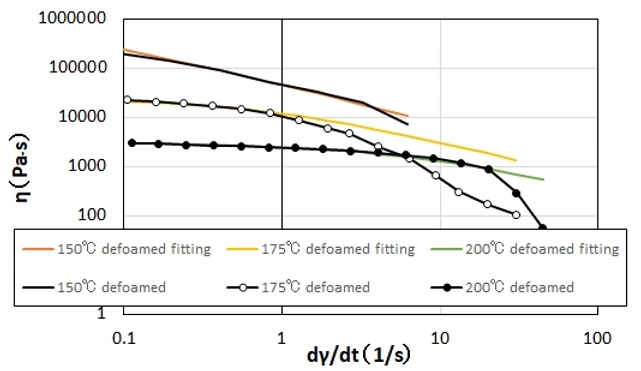

Now we try to use other models for explaining to viscosity of foamed and defoamed XPS because viscosity and its temperature dependency is very important to simulate the fire extension. Viscosity and volume change of melting XPS govern transportation of the flame with melting XPS. we believe our achievement would contribute to the improvement of accuracy of fire disaster simulation.

Foamed XPS(normal XPS) could not ride on the temperature dependency of cross WLF(colored line)

Defoamed XPS could ride on cross WLF during fire disaster(colored line, low shear rate ranged)