Dr. Leem and Mr.Ikeda (D1) have published their research on improving the durability and the mechanism of foam structure changes in graphite-added expanded plastic insulation materials (gXPS) in Composites Part A: Applied Science and Manufacturing.

Graphite-containing extruded expanded polystyrene insulation materials have increasing attention as superior products due to their lower thermal conductivity compared to conventional products, as well as their excellent long-term stability in mechanical properties and thermal conductivity retention.

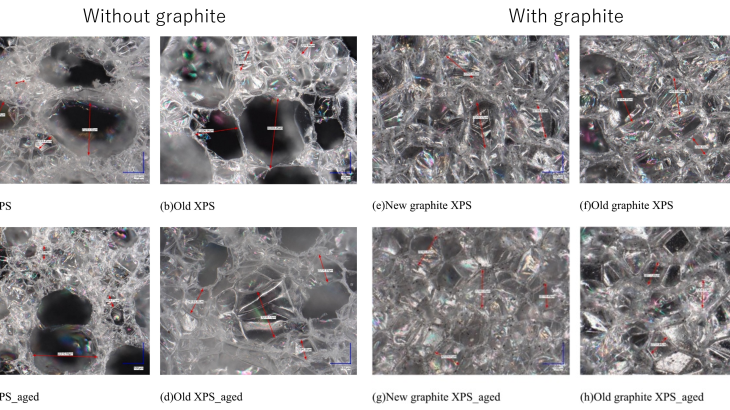

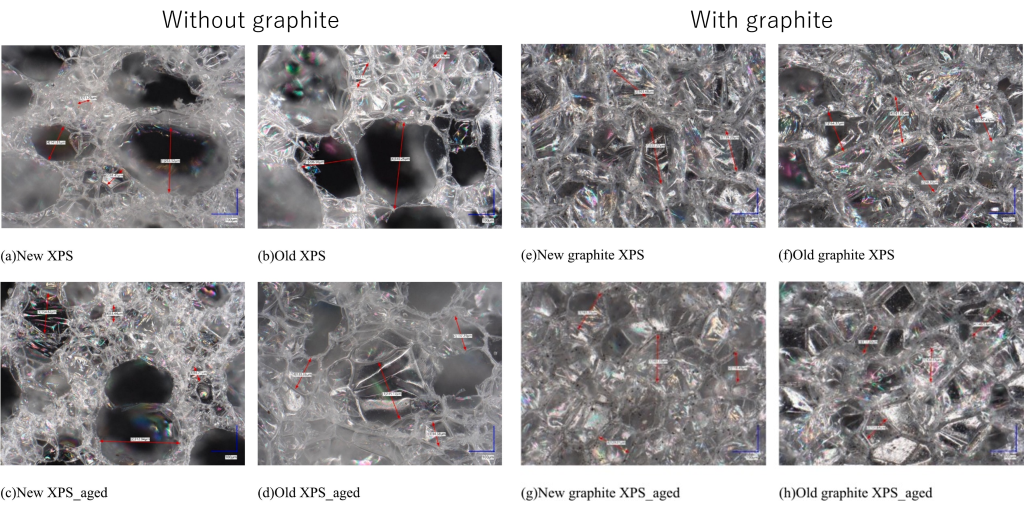

This study corresponds to the final chapter of Dr. Leem’s doctoral thesis on the long-term performance mechanisms and evaluation methods of foam plastic-based insulation materials. It incorporates all the analysis and evaluation methods for foam plastics (evaluation of foam structure, strut structure, chemical bond changes, and gel structure changes) developed by our laboratory to date. Dr. Leem mainly conducted the overall research, and Mr.Ikeda, a first-year doctoral student, developed a beautiful optical microscopy imaging technique for foamed plastics, which had been difficult to achieve until now, and finally completed the study.

In conclusion, graphite significantly alters the foam structure itself, contributing to the homogenization of the pore structure. In exchange, it eliminates fine pores and transforms the intermediate-sized pores into a homogeneous pore structure. This contributes to the long-term performance of the materials. Additionally, in previous studies, it was difficult to maintain consistency between the pore distribution measurements obtained by XCT and the results observed under an optical microscope. When observing the cells that constitute the foam under an optical microscope, the presence of various objective distances, combined with the highly irregular arrangement of the few-micron-thick films at various angles, made it extremely challenging to capture clear images due to light reflection and scattering. By addressing this issue, we have achieved consistency between XCT-based void distribution results and optical microscope images. This is expected to significantly contribute to the product development and performance evaluation of foam plastic materials in the future.

This is also related to the recently published JIS A1491 “Method for Evaluating the Convergence Values of Long-Term Thermal Insulation Performance of Building Insulation Materials” in Japan. Like structural materials such as concrete, insulation materials are increasingly being evaluated for their durability. Insulation materials play a major role in achieving “energy efficiency” for ZEB and ZEH certification, but their thermal insulation performance is not constant. Naturally, it changes over time.This is a given for materials. However, this concept has not yet been widely adopted in ignoring that “A material is never forever”. Therefore, it is believed that long-term use will require “thermal insulation retrofitting,” and buildings should be designed to accommodate for retrofitting insulation members. Our research group aims to contribute to both energy efficiency and durability of materials from a research perspective, collaborating with overseas institutions.

Microstructural changes of XPS foamed plastic adding graphite fillers analyzed by Py-GC/MS and X-ray CT, Composites Part A: Applied Science and Manufacturing, 2025,109132

https://doi.org/10.1016/j.compositesa.2025.109132