Our research mission is to study buildings and structures to let them more convenient, safer, and their lifetime longer based on material science. Especially, we are strongly interested in deteriorating mechanisms of materials and counter methodologies to stop deteriorating. It is very important for us to pursue the best way of measurement and analysis, and to contribute to society by publishing the latest data in order to settle important issues.

We have two main themes, concrete and polymer; both of them are important for buildings and structures. Generally, concrete-based materials are regarded as inorganic materials, and polymer-based materials are regarded as organic materials. However, in real buildings and structures, there are few pure materials; in most cases, these materials are used in combination, that is, the surface of concrete is impregnated with polymers, and calcium carbonate powder is mixed in polymer-based adhesive for jointing between iron and concrete. They have an extremely large number of inorganic-organic interfaces. Generally, because there are many unexplained points about inorganic-organic interface, if we treat it in a wrong way, it deteriorates easily and may cause an accident or disaster. On the other hand, in terms of excellent combinations, composites exhibit great performance in many respects and are widely used as excellent construction methods with many achievements.

Construction material is a very unique area dealing with both inorganic and organic materials. In order to deal with this diversity, we continue to challenge to acquire fundamental/advanced scientific knowledge and progress to understand the properties and interactions of various materials.

The following topics are our recent research works. We hope to contribute to our society through such works.

- 1. Research topic1:Degradation mechanism and durability of repairing agents coated on surface of structural materials.

- 2. Research topic 2: New deterioration behaviors of building materials caused by recent climate changes in cold regions

- 3. Research topic 3:Reaction mechanism of repairing materials

- 4. Research topic 4:Degradation mechanisms of polymers for building and construction use.

- 5. Research topic 5: Degradation mechanisms of insulation materials

Research topic1:Degradation mechanism and durability of repairing agents coated on surface of structural materials.

Could repaired buildings sustain their performance for a long time ?

How do we verify the repairing quality?

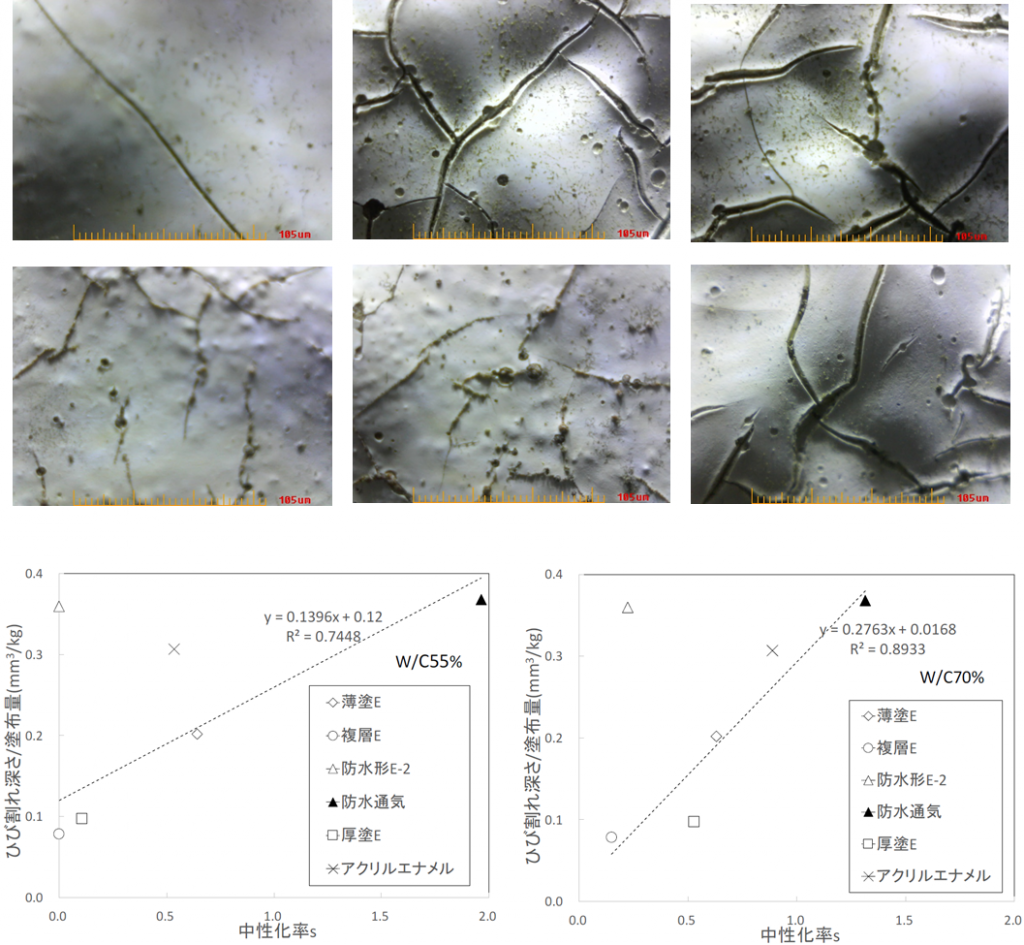

Visual inspection is a common methodology for deterioration of repairing materials applied to the surface of concrete and other exterior materials. However, this was not clearly related to the actual progress of deterioration. Therefore, we focused on the cracks on the surface of the repair material and we demonstrated that the barrier performance of the material is related to the crack width/coating amount per unit area, using test pieces exposed outdoor in 30 years.

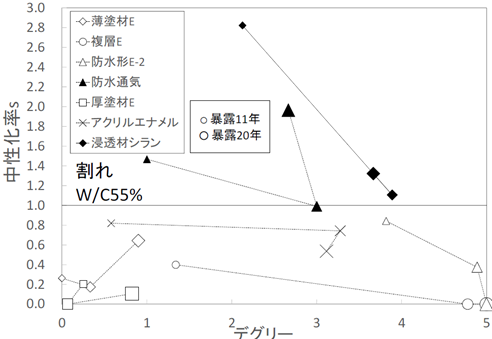

The polymeric repairing materials applied to the surface of existing buildings are easy to get dirty over the years. The existing degree method based on visual inspection tends to evaluate color change and loss of gloss in materials as the deterioration of materials. As Figure 1 shown, there was little connection between the degree of poor appearance and relative carbonation depth of coated surface to non-coated surface.

We focused on microscopic cracks which could be more strongly related to the barrier property of the coated surface, and as Figure 2 shown, there is a linear relationship between crack width/coating amount per unit area, regardless of the type of repair material. ( marker “△” in Figure 2 deviates from the tendency, and it is an extremely hydrophilic coating, which is very different from other types of coatings.)

Although it is general in concrete engineering that the degree of cracks influences to barrier properties of surface materials, there are not many cases in demonstrating that the same tendency can be seen for various coating films. This fact can become the basis of diagnostic criteria in maintenance.

In reality, even if kept clean to the naked eye, there are many small clacks that are hard to see. This study suggests that decrease of barrier performance by cracks affects decrease in durability of buildings, regardless of its appearance.

and relationship between crack depth/amount of coarings per unit surface and relative carbonation depth

Research topic 2: New deterioration behaviors of building materials caused by recent climate changes in cold regions

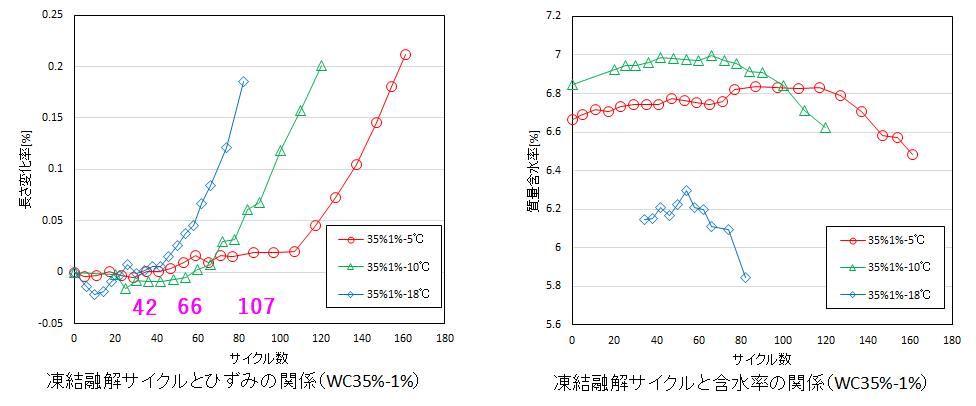

Recent climate changes in cold regions like Sapporo city decrease frost damage in winter, but dry and wet cycles in summer become increased and promote cracks by drying shrinkage.

What will happen in existing concrete in recent cold regions under new weather conditions?

It has been reported that annual number of freeze-thaw cycles decreases due to global warming in most cold regions except near the polar regions. The Japan Meteorological Agency and the Ministry of the Environment have provided information on climate change forecasts in Japan with many reports (For example, Climate Change Prediction Information Volume 9 (2017), etc.), and it is thought that there is the similar tendency in cold regions of Japan with other cold regions. On the other hand, depending on the region, it is expected that the number of rainfalls and the number of dry days in summer will change significantly, and the above report points out that it is highly likely that the amount and the number of precipitation will increase in Hokkaido. For concrete structures, when the temperature rises and the number of dry and wet cycles in the summer increases, the risk of rebar corrosion in concrete in the summer may increase. For example, it is not desirable for reinforced concrete to continue to be exposed to the conditions of dry and wet cycles in summers.

It is necessary to consider the relationship between temperature fluctuations and frost damage in recent winter, and additionally, how the corrosion of reinforcing rebars in concrete is related to crack generation caused by the amount and the number of precipitations.

Figure 3 shows the relationship between the length change rate and the water content, which are indicators of frost damage caused by freeze-thaw cycle with different minimum temperatures. The lower the minimum temperature, the more serious damage caused by frost damage. For example, in the figure on the left, you can see that the rate of change in length increases sharply early in the freeze-thaw cycle. The pink numbers indicate the number of cycles showing the starting point for the rapid deterioration of destruction. This is a common behavior in fatigue tests in fracture mechanics. However, although the water content tends to be constant, the relationship with the number of cycles is unclear compared to the length change rate.

It seems that frost damage will be less likely to occur in cold regions because the minimum temperature will rise due to global warming. However, as Figure 3 shows the results of concretes with specific mix proportions, we cannot explain the behavior of the frost damage caused by freeze-thaw cycles in other mix proportions. The change of strain, strength, and elasticity of concrete caused by frost damage need to be explained based on a theoretical approach in order to predict performance and durability of various types of concrete in cold regions.

The goals of our research are to formulate the time-dependency relationship between mechanical properties of concrete(strain, strength, and elasticity) and frost damage, regardless of concrete mix proportion, and predict the starting point (i.e. pink numbers on the left of Figure 3) where the critical point of value changes caused by frost damage.

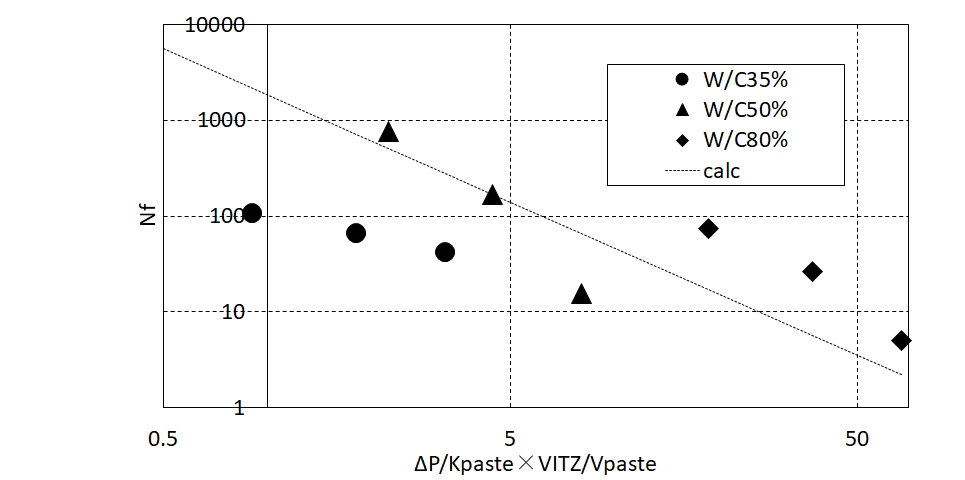

Figure 4 shows the result of comparing the relationship between the Cryo suction pressure in the transition zone of concrete and Nf meaning “cyclic number to critical failure” in Fracture mechanics. Liquid water contained in the transition zone is partially frozen and remained liquid water becomes compressed because of the volumetric expansion of frozen ice, and migrates into other jointing pores. we consider such Cryo suction pressure of liquid water in freezing-thawing cycles make initial damage to concrete and it connects to the starting point Nf of critical failure as explained above.

Regardless of the water-cement ratio, there is a possibility that there is a certain relationship between Cryo suction pressure in the transition zone and Nf.

Research topic 3:Reaction mechanism of repairing materials

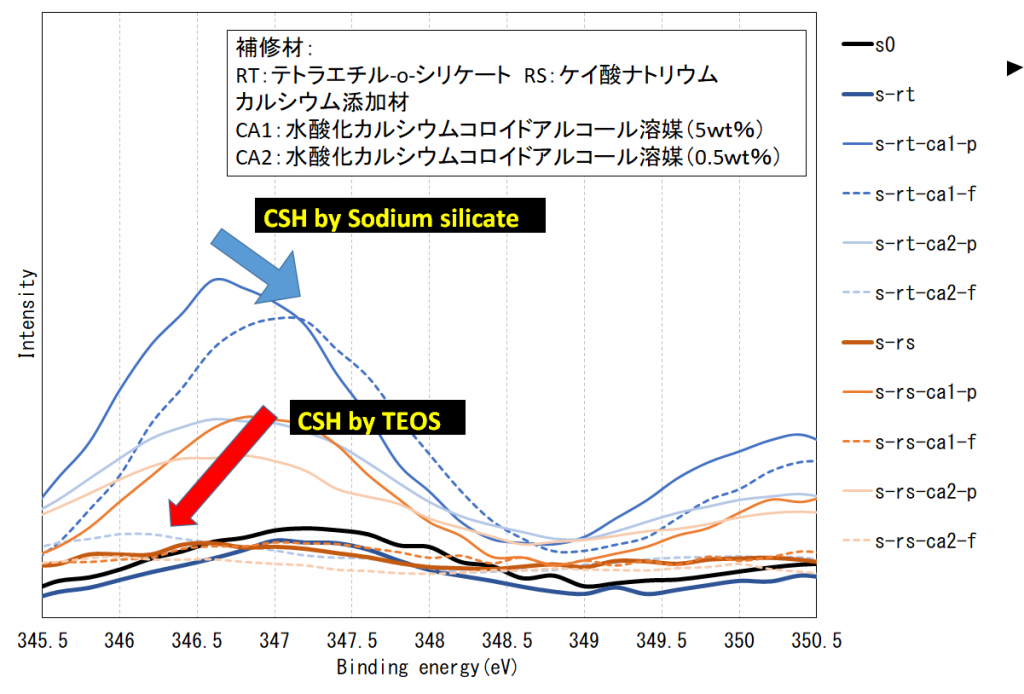

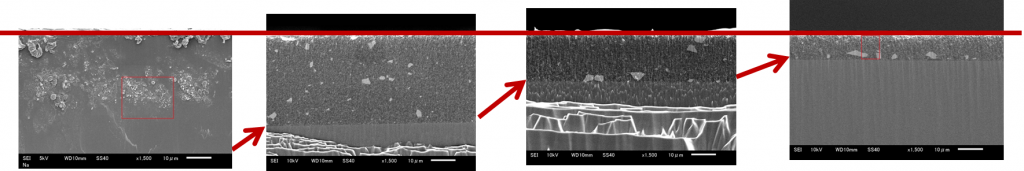

How does repairing materials react with buildings surfaces and improve barrier properties? How should we apply repairing materials to building surfaces? Many repairing materials and methodologies are established

over the world, however, they are used based on the company’s instructions. Such instructed amounts and methodologies are not necessarily optimal, and the mechanism of reaction in several types of building surfaces is not consistent. We try to clarify reaction mechanisms and suggest optimal procedures of repairing materials based on scientific analysis.

Research topic 4:Degradation mechanisms of polymers for building and construction use.

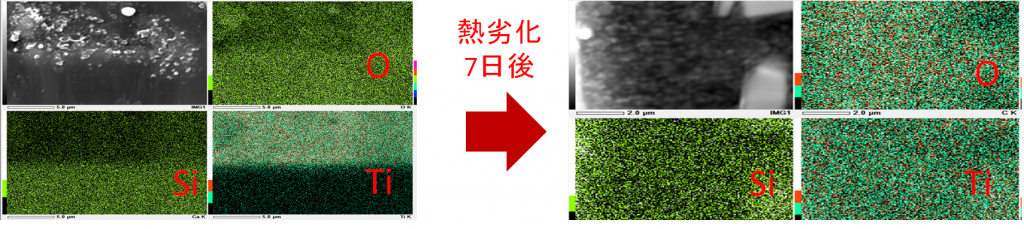

The deterioration mechanisms of repairing/covering/water-proofing polymer composites for building surfaces, such as urethane and silicone are not investigated scientifically in aspects of longevity. We have experimentally demonstrated the hypothesis that fillers could migrate in polymers in the process of deterioration and re-arranged of polymers.

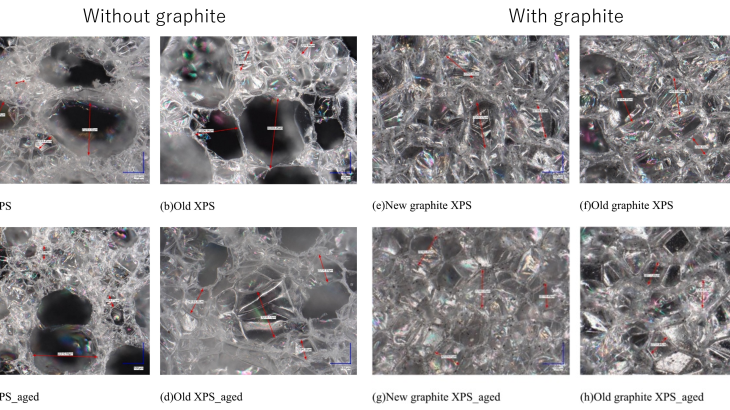

Research topic 5: Degradation mechanisms of insulation materials

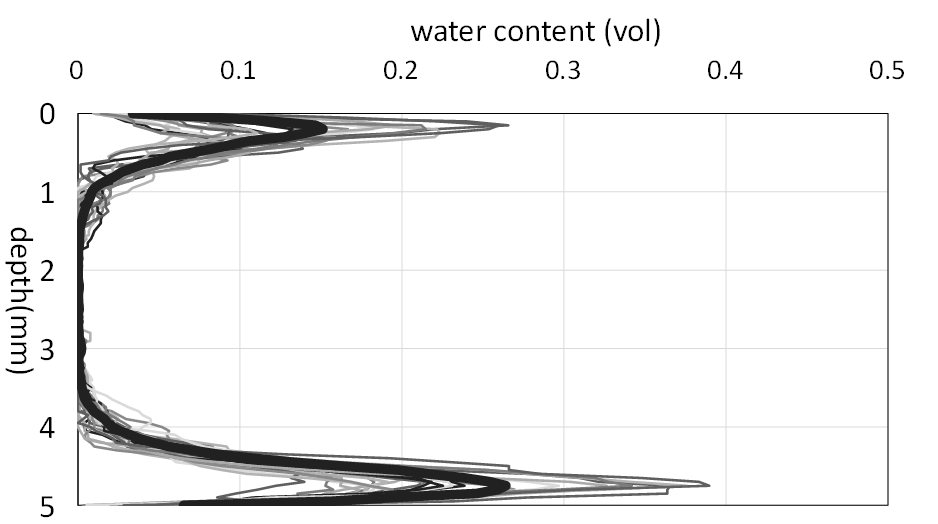

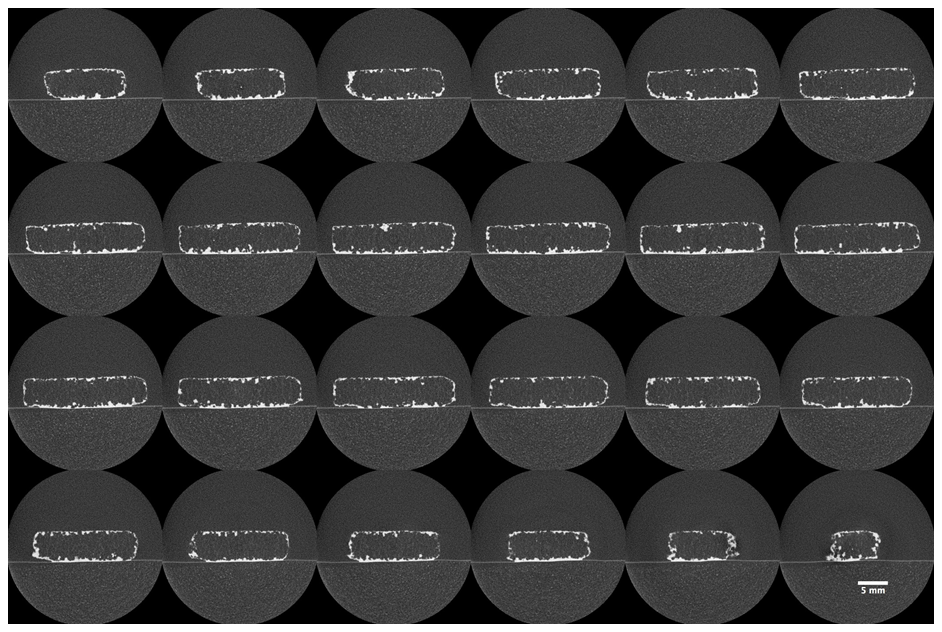

When the temperature is rapidly decreased in a hot and humid environment, water will be condensed as liquid water inside the material.

There are many reports in warm regions that plastic insulation foams absorb water, and the thermal conductivity rises in a short period. This phenomenon affects energy-saving issues in buildings, and assumes to be occured in warm/humid region over the world, such as Japan, China, Korea and other warmer asian countries.

We exposed plastic insulation foams into cold-hot cycles with high humidity assuming to install the foams in walls, and succeeded in measuring the water distribution of the foams. Now ZEB and ZEH need to keep thermal conductivity in insulation, we have to investigate such phenomenon and consider how to prevent from it.