In the case of polymers, swelling can be a guide because it basically indicates that the barrier performance degrades as the free volume increases. Swelling is increase in volume as a result of the repulsive effect caused by small molecules entering the gaps that can enter. And in general, the barrier performance often deteriorates in this case. However, if the free volume is reduced by a micro-shrink phenomenon and it affects an increase of macro-cracking and coarse gaps, the swelling degree and the barrier performance may also decrease at the same time. Therefore, for polymers that are responsible for the barrier performance of the surface layer of many materials, the change in swelling degree means a change in gel structure, which is one proof that the diffusive performance have changed.

More specifically, it is important to measure the diffusive performance directly.

In the case of polymers, diffusing penetrant gives a constant stress effect and it changes the gel condition. For instance, thickness dependence such as Pore flow and mutual dependence of multi-gas are seen as reported by Tanioka et al. According to him, basic research on the barrier performance of polymer coating used to be often conducted, but composite and architectural coatings seem not treated. Professor T also said it might have been difficult to match the values of polymer in the interdisciplinary discussion between chemistry and architecture at that time.

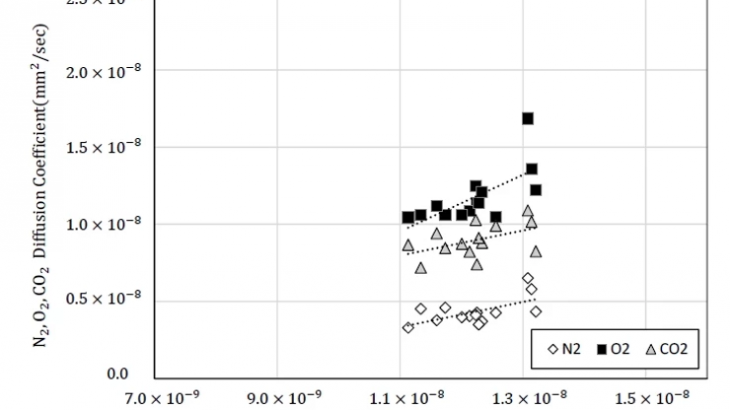

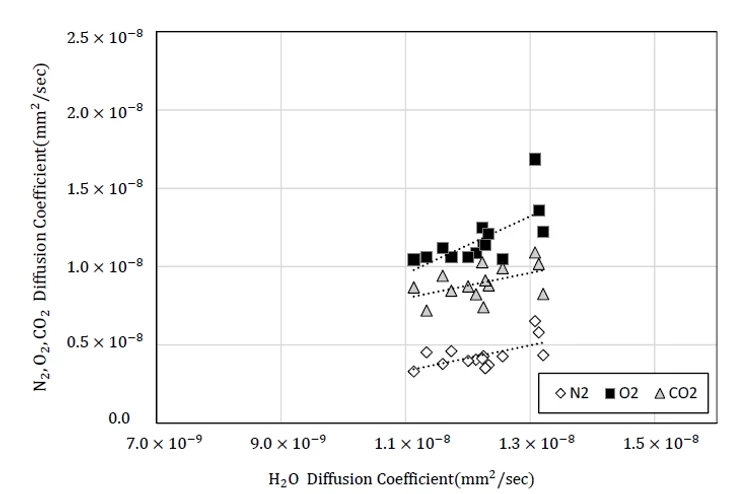

It is difficult to measure polymer coating for construction, which is particularly difficult to isolate even now. But for example, the diffusion coefficient, solubility coefficient, and gas permeation coefficient of various gases can be obtained under limited conditions by using vacuum MS as shown in my paper. In this case, in a polyurethane-based composite coating, other molecules are diffused by being pulled by water molecules.

Relationship between the diffusion coefficient of water and other gases in the humidity-controlled modified silicone coating film

It is natural these performance change depending on the type of polymer and whether it is above or below the glass transition point, and moreover, performance degrades due to changes in deterioration external forces such as ultraviolet rays and temperature and humidity, so durability need to be considered.

In this case, it seems important to measure the swelling degree and diffusivity of deteriorated polymers. However, the evaluation tests on these performances of building polymers are actually not very sufficient.

What we usually consider are “Yellowing” and “Color difference”. However, the change in color does not necessarily mean that the barrier performance is reduced, but in short, the color-developing molecules are generated. Or rather, the barrier performance may be improved. In fact, in most of various research reports, the color difference is not so proportional to the exposure time, but rather moves up and down.

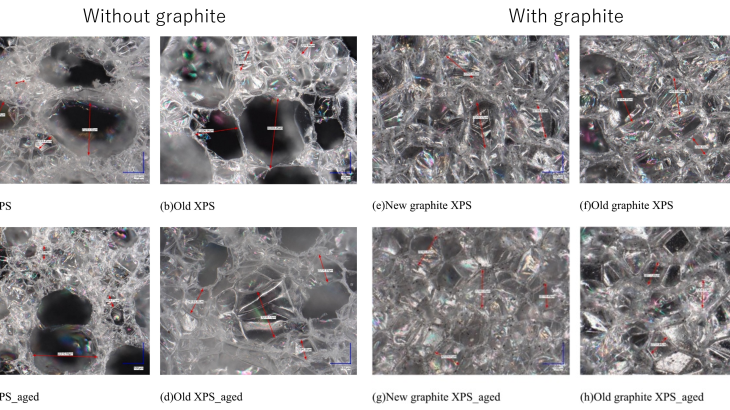

And also just because the color doesn’t change doesn’t mean that the barrier performance is maintained. Rather, the color remains the same and the barrier performance is often greatly reduced. Especially in composites containing filler, it has been reported that polymer on the filler interface or the surface layer of the filler follows a reaction pathway completely different from that in the bulk state due to interaction.

From these facts, investigating yellowing does not play a very important role in evaluating performance, and other authorized methods for evaluating barrier performance are not well defined.

“If it’s okay to look at it, it’s okay for performance.”

may be close to a dentist makes a diagnosis like;

“You don’t have periodontal disease because it looks okay.”

Then, what about other method? It is probably the use of surface contact angle method…

When the surface area and physical properties change at the same time, it’s more important to understand why the performance change rather than whether the experimental results can be used in the field. I’d like to describe in detail next time why the contact angle method is not suitable for evaluation.