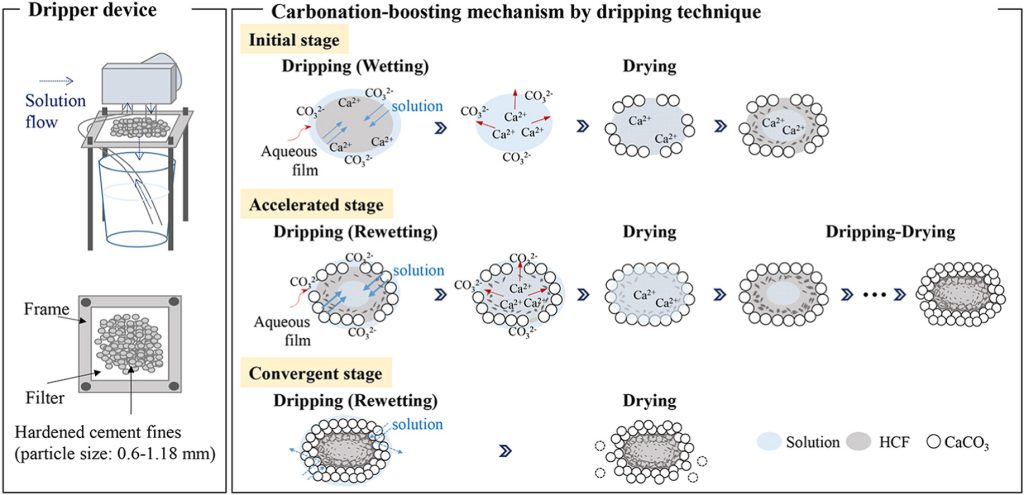

Assisstant Prof. OH and Prof. Kitagaki has been published a pepar on a boosting method for fixation of atmospheric low-concentration CO2 to cementitious materials. This is a research project that we have been working on jointly with Prof.Noguchi and Prof. Maruyama Laboratory of the University of Tokyo for the past year or so, and the technique is intended to be manufactured as a CCC raw material production process in NEDO Moonshot project named as C4S project. It is ongoing to set up a larger scale process. The features of this method, originally developed by Hokkaido University, are as follows.

Looking at research trends in concrete and CO2 fixation over the world, most of the research are focused on improving the reaction rate of CO2 fixation to cementitious materials by using concentrated CO2 and additives. On the other hand, the use of concentrated CO2 is practically limited to limited locations, such as those with exhaust gases, and the transportation of concrete and cementitious materiasls increase CO2 emissions. If it becomes common practice to evaluate and assess the CO2 fixation amount of concrete, the actual CO2 fixation amount may be greatly diminished. However, at present, not much attention has been paid to this point.

In our laboratory, we have anticipated this point and insisted on using dilute atmospheric CO2 as it is, instead of concentrated CO2. This method also uses atmospheric CO2 and can accomplish rapid fixation of CO2 simply by leaving it anywhere.

It uses very little energy; it only requires sprinkling of drinking water once a day under certain conditions. The period of time is as short as 3 to 7 days at most, which is sufficient for practical use.

No reagents or additives are used. Therefore, there are no special safety concerns.

Compared to the “CO2 fixation at 60% relative humidity,” which is generally considered to have the fastest carbonation rate, our method achieves 1.5 to 2 times faster CO2 fixation during the first 3 days of exposure to the atmosphere. Therefore, from a practical point of view, this method realizes extremely short-term and high-speed carbonation.